CNC Machining Parts from China: Quality and Precision Redefined

CNC (Computer Numerical Control) machining is a revolutionary manufacturing process used extensively in the production of precision parts and components across multiple industries. One country that has excelled in this field is China, a global leader in providing high-quality CNC machining parts at competitive prices. In this comprehensive article, we will delve into various aspects of CNC machining in China, particularly focusing on its advantages, processes, and how to find the right manufacturer.

Understanding CNC Machining

CNC machining involves the automated control of machining tools through a computer. It enables the creation of complex shapes and designs that meet stringent quality standards. The process is highly efficient, reducing the manual labor required and minimizing human error.

The Benefits of CNC Machining Parts from China

- Cost Efficiency: One of the most compelling reasons to source CNC machining parts from China is the significant cost savings. Lower labor costs and economies of scale allow Chinese manufacturers to offer competitive pricing without compromising quality.

- Advanced Technology: Chinese manufacturers have access to cutting-edge CNC technology and machinery, enabling them to produce intricate and precise components that meet international standards.

- Experienced Workforce: With years of experience in manufacturing, Chinese workers are skilled in CNC machining processes, ensuring high-quality outputs and reduced production times.

- Wide Range of Materials: Chinese manufacturers can work with various materials, including metals, plastics, and composites, making it easier to find the perfect fit for your project.

Key CNC Machining Processes

China excels in various CNC machining processes, including:

CNC Turning

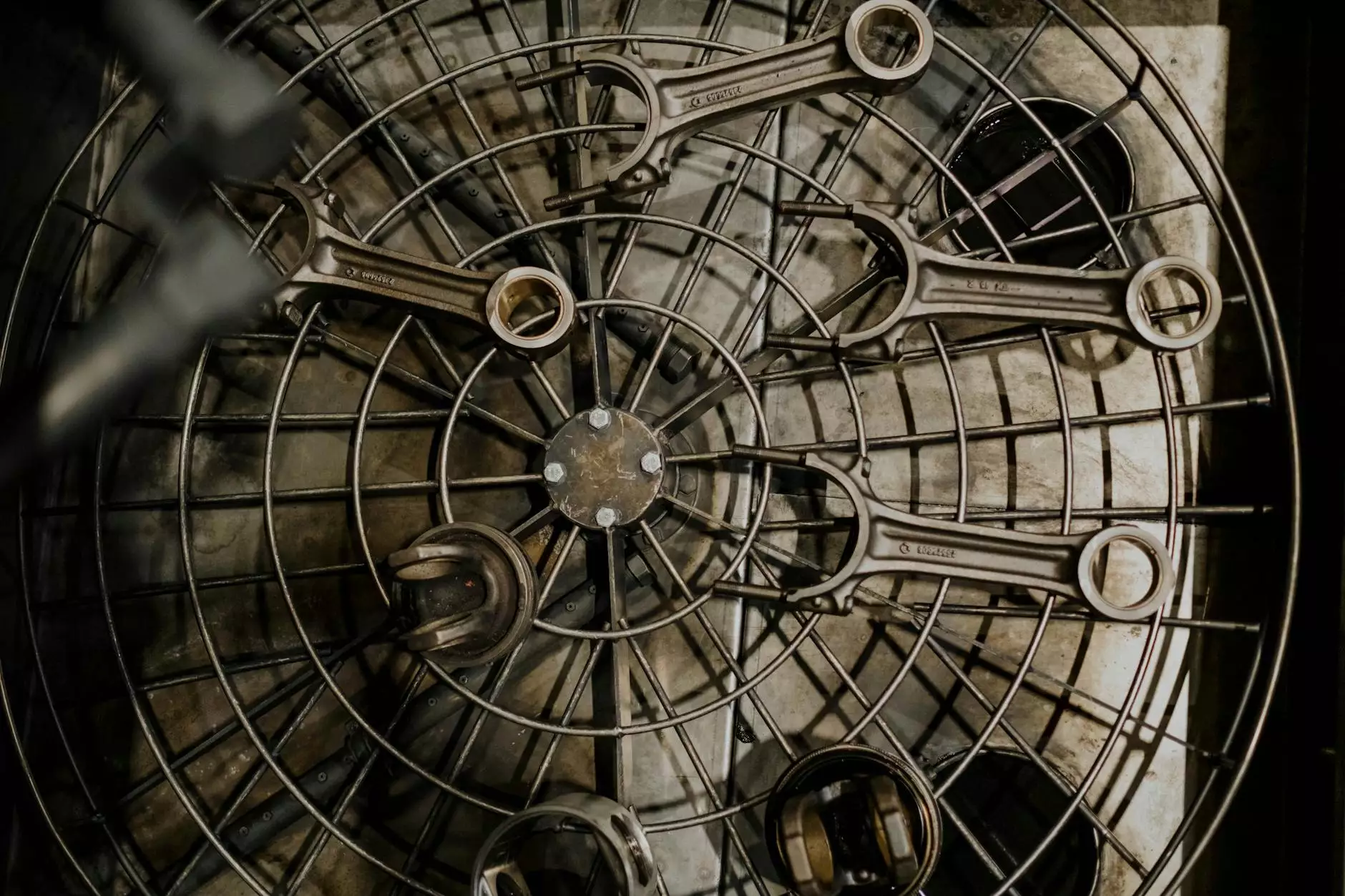

CNC turning is a process used to create cylindrical parts where the material is rotated against a cutting tool. It is ideal for producing shafts, bushings, and rings with high accuracy.

CNC Milling

CNC milling employs rotating cutting tools to remove material from a workpiece. This process is versatile and can create complex shapes, slots, and flat surfaces.

CNC Grinding

CNC grinding is used for finishing processes and producing tight tolerances. It’s particularly effective for hard materials and achieving superior surface finishes.

CNC Electrical Discharge Machining (EDM)

EDM uses electrical discharges to remove material and is ideal for intricate designs and achieving high accuracy in hard materials.

Choosing the Right CNC Machining Manufacturer in China

The selection of a reliable CNC machining manufacturer is crucial for ensuring the quality and timeliness of your products. Here are some key considerations:

- Research and Reviews: Investigate potential manufacturers by reading reviews and testimonials. Look for companies with a strong reputation for quality and service.

- Quality Certifications: Ensure the manufacturer holds relevant quality certifications, such as ISO 9001, to guarantee they adhere to international quality standards.

- Production Capabilities: Evaluate the company’s production capabilities and technologies. They should have advanced CNC machinery to support your specific needs.

- Communication: Effective communication is vital. Choose a manufacturer that is responsive and easy to communicate with for smooth collaboration.

- Sample Products: Request samples of their work to assess the quality of the CNC machining parts they produce.

Applications of CNC Machining Parts

CNC machining parts play a pivotal role across various industries. Here are some common applications:

- Aerospace: Precision components for aircraft and spacecraft, where reliability and accuracy are critical.

- Automotive: Parts such as engine components, gears, and brackets made to withstand rigorous conditions.

- Medical Devices: Custom parts for medical equipment, ensuring compliance with strict regulatory standards.

- Consumer Electronics: Components used in smartphones, laptops, and other electronic devices requiring fine tolerances.

Quality Assurance in CNC Machining

Quality assurance is a fundamental aspect of CNC machining in China. Manufacturers often implement strict quality control processes, including:

- In-Process Inspection: Regular checks during production to ensure that parts meet specified tolerances and quality standards.

- Final Inspection: Comprehensive inspections at the end of the production process to verify that all parts adhere to quality specifications.

- Use of Advanced Measurement Tools: Employing tools such as coordinate measuring machines (CMM) for accurate measurement of part dimensions.

Environmental Considerations in CNC Machining

There is a growing awareness of environmental sustainability in manufacturing practices. Leading CNC machining companies in China are adopting greener practices, such as:

- Waste Reduction: Implementing processes that minimize scrap and waste material.

- Energy Efficiency: Utilizing modern machinery that consumes less energy, contributing to lower carbon footprints.

- Recycling: Recycling scrap materials whenever possible to promote sustainable practices.

Conclusion: The Future of CNC Machining Parts in China

As demand for high-quality CNC machining parts continues to grow globally, China's position as a leading manufacturer remains strong. With its advanced technology, skilled workforce, and commitment to quality, China will undoubtedly play a crucial role in the future of precision manufacturing.

By understanding the advantages and processes involved in sourcing cnc machining parts china, businesses can make informed decisions that enhance their operations and product offerings. Whether you’re in the aerospace, automotive, or electronics industries, finding the right manufacturer can lead to significant operational efficiencies and cost savings.